- products

High-Speed Automatic Liquid Horizontal Premade Pouch Doypack Packing Machine

Application:

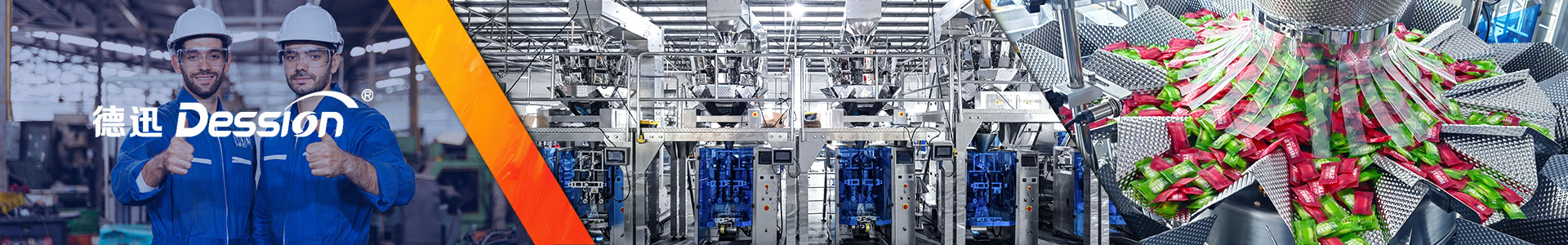

Application: This liquid filling packing machine is composed of a liquid pump and a host packing machine. It is suitable for all kinds of liquid products and capable of packing different pre-made bags. It can be applied to various liquids including honey, milk, oil, ketchup, paste, sauce, fruit juice, hand wash, laundry liquid and so on. Moreover, after replacing the metering device, it can also be utilized for packaging granular and powder products.

Kindly Reminder:

Our team of R & D engineers is quite experienced and they are able to customize packaging solutions based on the characteristics of your products.

Packing Exambers:

| Type | DS-160, DS-160Y, DS-210 |

|---|---|

| Bag Type | 3-side, 4-side sealing bag, Doypack, Box Pouch, Zipper Pouch, Stand Up Pouch, Stand Up Pouch With Zip |

| Bag Size | 110 – 230mm*80 – 160mm(L*W), 70 – 100mm*110 – 230(L*W), 100 – 210mm*110 – 320mm(L*W) |

| Filling Range | 10g-100g, 10g-100g, 10g-1kg |

| Packing Speed | 25 – 50bags/min(speed is determined by the product filling quantity), 20 – 45bags/min(speed is determined by the product filling quantity), 20 – 50bags/min (speed is determined by the product filling quantity) |

| Total Power | 2.0KW, 2.0KW, 2.0KW |

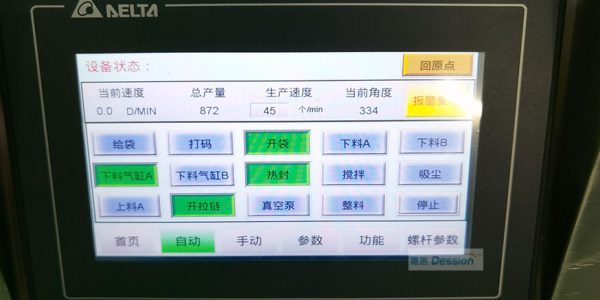

| Work Flow | 1.Giving bag 2.Pick up the bag(coding) 3.0pen the bag up and down 4.Feeding and jolting 5.Heating sealing 6.Output of product |

| Dimensions | 1750mmX1285mmX1360mm(L*W*H), 2140mm X 1366mmX1360mm(L*W*H) |

| Collocation | Screw metering.screw elevator |